Ultrasonic leak detection is a popular technique used to identify and locate leaks in industrial and commercial settings that use compressed air. The ultrasonic microphone can detect the high-frequency sound produced by the leak and can direct the user to where the leak is located with a high degree of great accuracy. Over the years there have been many types of Ultrasonic Leak detection methods.

Compressed air leaks are very common, persistent, and can be very costly when left undetected. Smart Ultrasonic leak detectors are extremely valuable in any manufacturing facility or industrial plant that uses compressed air as they can do bulk of the manual work and support continuous improvement models.

Traditional Leak Detection Methods

Traditional ways of finding compressed air leaks include a well-trained ear of an experienced facility employee, spraying soapy water onto the pipe, component, or joint area being investigated and looking for bubbles to form, or through sound using ultrasonic microphones, heterodyned to an audible level, allowing a trained user with headphones to pick up the high-frequency noise associated with leaking compressed air.

Another approach to overall system integrity assessment, and hence determination of system leakage, involves a system pressure decay test. These are typically performed at shutdown (and require an isolated system), with all operational systems maintained at a set and monitored pressure. If there is no pressure drop in the system over time, there are no leaks. If there is a pressure drop, that would indicate that there is likely a leak (or leaks) somewhere in the system, and by monitoring the decay over time, the overall loss can be determined. However, this method only confirms that there is system leakage but does not detect the source of the leak(s). It can also be an approach that is difficult to schedule as facilities generally plan shutdowns for critical operational maintenance and repair activities which cannot be easily completed online, hence requesting to pressure and hold the system in that state for a set number of hours would generally be met with resistance.

These traditional methods can all help to detect leaks, but all have challenges and rarely support a user with the complete leak management life cycle, I.e. detection through to repair and improvement.

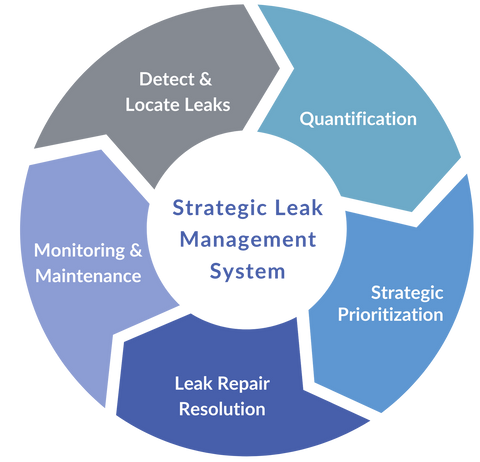

Prosaris Strategic Leak Management Cycle

Image 1.1: The image demonstrates the leak management life-cycle that is the foundation of our leak management model. Smart leak detectors possess traits and features to that assist and simplify each stage of leak management and supports continuous improvement energy systems.

What is a 'Smart' Ultrasonic Leak Detector

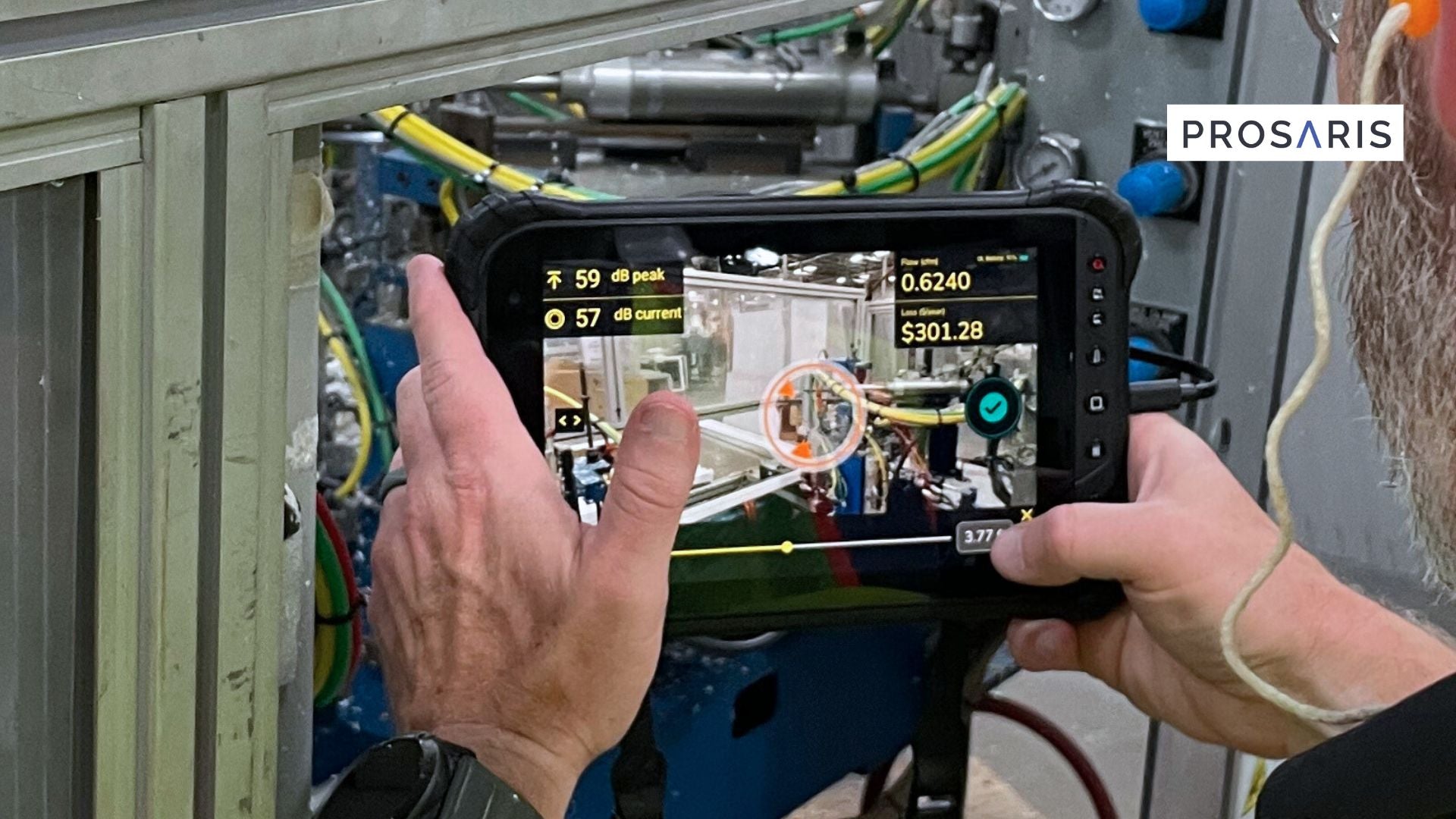

Smart ultrasonic leak detectors work in conjunction with smart phones and tablets, giving users additional capabilities and support to simplify each stage of leak detection and management. They have added features that extend beyond locating a leak. Along with being able to visually locate the leak, the smart ultrasonic leak sensor allows the users to quantify them in real-time, calculate the flow accurately, and capture all the technical leak data required for prioritization and loss analysis.

Another important benefit is the ability to add pictures and location markers to these records and store it as a complete leak record. This data can then be synced into the cloud-based leak management platform. It helps external teams who come in for repair to easily identify corresponding leaks and help for easy re-verification.

How does Leak Tracking work?

All leak event records in the facility can be accessed by administrators who can review and look at the progress and energy consumption trends over time. They can also track the status of leaks (when they were recorded, fixed, and checked on and by whom). Administrators can assign leaks to other users to manage, repair or reverify post repair. The users can also keep track of all leaks assigned to them and effectively complete tasks towards leak resolution.

The annual monetary loss can be computed, measuring the company’s financial loss corresponding to the amount of air leaking from the compressors and system. By analyzing the leak data, we understand the baseline of energy loss from leaks, and report over a period of time. It can also help show areas that need improvement in the facility.

-

Efficient Time and Task Utilization: Achieve effective leak detection and quantification within minutes, saving valuable time. Utilize tools like smart leak tags to swiftly retrieve leak records, bypassing the need to sift through lengthy CSV files to locate specific leaks, resulting in significant time savings. Smart devices also open the door for effective task monitoring, prioritization and tracking through to completion.

-

Continuous Improvement Approach: Embrace a continuous improvement model for leak management, recognizing that it is an ongoing process rather than a one-time task. Smart ultrasonic leak sensors, when implemented as part of an energy management system, can excel in maintaining comprehensive leak event records, helping you crunch data and extract substantial savings with each completed cycle.

-

Streamlined Workforce Training: Digital devices are adept at scanning for leaks, simplifying the process of tracking and accurately quantifying leaks, thus reducing the manual workload for users. This streamlined approach eliminates the necessity for solely relying on "Certified professionals" to operate the equipment. With brief onboarding sessions and a wealth of support "how-to" videos, anyone can promptly commence leak detection without extensive training. This empowers teams to regularize and conduct more leak audits and include them as part of their regular workflow.

-

Strategic Data Insights: Extracting valuable insights from data is crucial for informed decision-making. Customizable Dashboards provide strategic analysis of leak event data, offering visual representations and insights into various categories such as Leaks found vs Leaks fixed, identifying high-cost leaks, determining immediate repair needs versus monitoring requirements, enabling the formulation of value-based resolutions based on a comprehensive analysis of thousands of records.

- Reporting Energy Savings: The reporting feature includes comprehensive records from both identified leaks and the resulting cost savings from their resolution. These crucial data points are systematically tracked and recorded throughout the entire leak management process. By simply clicking a button, users can instantly generate comprehensive reports, complete with visual documentation, eliminating the need for time-consuming manual compilation of separate reports.The advanced reporting capabilities prepares complete detailed reports in formats suitable for internal reporting, and to report to energy management utility programs.

Conclusion

Investing in smart ultrasonic leak detection technology offers businesses a reliable and efficient solution for detecting and locating leaks in industrial and commercial settings quickly and the ability to regularly conduct audits. By quickly pinpointing leaks, it enhances safety, reduces energy waste, and outperforms existing detection methods. This not only saves time and money but also enables businesses to maintain their operations efficiently.

Prosaris' OL series devices embody all the necessary aspects of a smart ultrasonic leak detector, including excellent leak detection skills and a comprehensive leak management system for capturing, analyzing, and managing leaks. With the ability to identify and prioritize leaks early on, these detectors help businesses reduce energy waste, prevent costly maintenance, lower energy bills, and avoid expensive repairs, ultimately leading to significant long-term cost savings.